Ex.2 PLASMA-BLASED COATINGS PROCESSES FOR NANOCOMPOSITE MATERIALS

CONTACT : JEAN-PASCAL BORRA

In-flight coating of NP by post-DBD reactive PE-CVD of gas precursor for thermo-stable SiO2 coating of photocatalytic NP (2015-19, 1 PhD in collaboration with Prof.Weber from TU Clausthal, [12, T34])

Coatings of agglomerated NP is used to improve thermostability to limit the surface reduction by melting of catalytic agglomerates. Silicon oxide is one of the preferred nontoxic and almost inert coating materials. Liquid coating methods imply washing, drying and separation steps, with residual impurities from solvents contaminating the final solid coatings. Therefore, gas-phase coating methods are generally preferred (e.g. atomic layer deposition and plasma enhanced chemical vapor deposition PE-CVD). Here, a plasma-based aerosol process has been proposed and validated for in-flight coating of particles by post-Plasma SiOx coating.

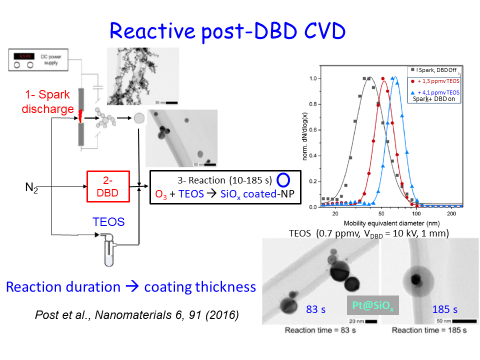

It has been shown that non-thermal plasma filaments induced in a dielectric barrier discharge (DBD) at atmospheric pressure trigger post-DBD gas phase reactions with tetraethyl orthosilicate (TEOS) precursor downstream of the DBD.

1) Pt- catalytic NP production by spark-surface interaction, followed by 2-3) post-DBD Reactive Nucleation also called PE-CVD ; (right) size distributions of Pt- NP from sparks only, compared with the same coated aerosol with DBD on for 2 TEOS concentrations

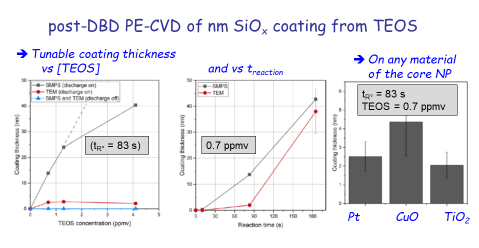

Such post-DBD injection of gaseous organo-silicon precursor avoids electrode coating and discharge evolution to achieve a steady fluxes of active species downstream the so-stabilized DBD, with subsequent controlled thickness of SiOx coatings, versus TEOS concentration and reaction duration.

Homogeneous solid SiOx coatings of spherical and agglomerated metal and metal oxide nanoparticles (Pt, CuO, TiO2) have been achieved with controlled thickness from nanometer to micrometer.

The reader can find details on (i) operating conditions to be tuned to cover preferentially the interparticle contact zones between primary particles of agglomerates, (ii) improved thermal stability, related to higher sintering temperatures of so-coated agglomerates of catalytic Pt-NP, as well as (iii) tunable photoactivity catalytic Pt-NP agglomerates.

Laboratoire de Physique des Gaz et des Plasmas

Bat 210, rue Henri Becquerel

91405 Orsay Cedex

Tél : (33) 01 69 15 72 51

RÉSEAUX SOCIAUX